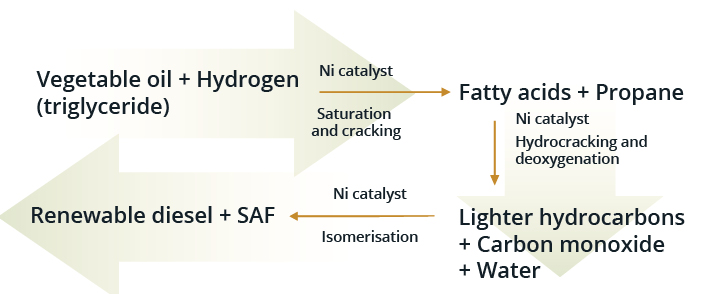

The increased use of green diesel to combat climate change and the depletion of fossil fuels, is creating more intensive investigation into cost-effective catalysts such as nickel-alumina playing a key part in the process.

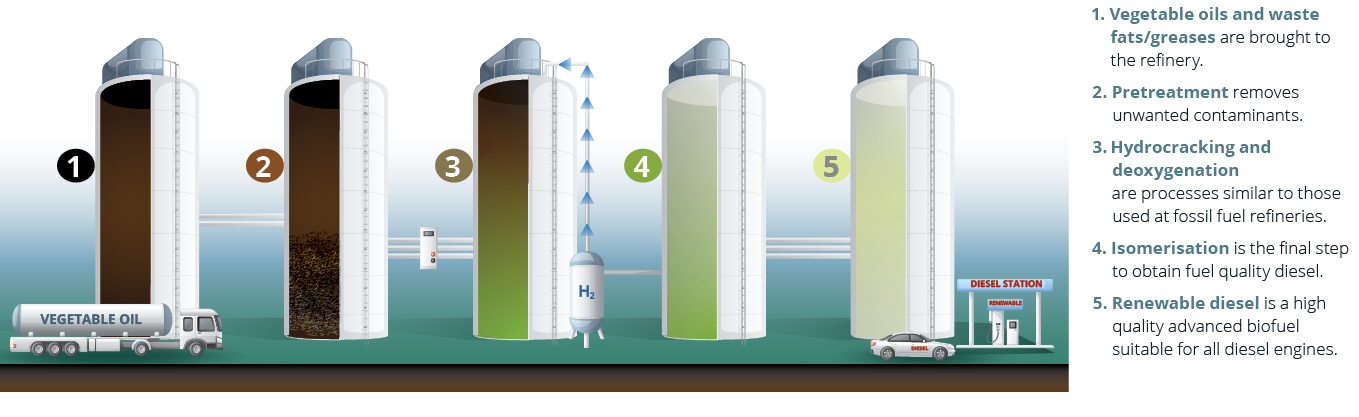

The vast majority of renewable fuels today are either ethanol (corn-based in the US and sugar-based in Brazil) or biodiesel, which is made by transesterification of vegetable oils. Both ethanol and biodiesel suffer from blending constraints limiting their use as well as lower energy content compared to either gasoline or petroleum-derived diesel. Renewable diesel (RD) is made by hydroprocessing vegetable oil, and waste fats and greases, in a process very similar to those used to make diesel in a conventional refinery. Renewable diesel’s close chemical relative, sustainable aviation fuel (SAF), can be made by different processes, including hydrotreating vegetable oils, if the oil feedstock has the appropriate chemical composition. Renewable diesel meets all the conventional specifications for diesel fuels, so it can be used without blending, unlike biodiesel.